stripping, scabbling

Is this your challenge?

Dismantling or asbestos removal operations requiring optimal dust extraction

On walls, ceilings and floors

-

Concrete, coatings... scabbling

- Removal of paint from metal or concrete surfaces

What tools do we use?

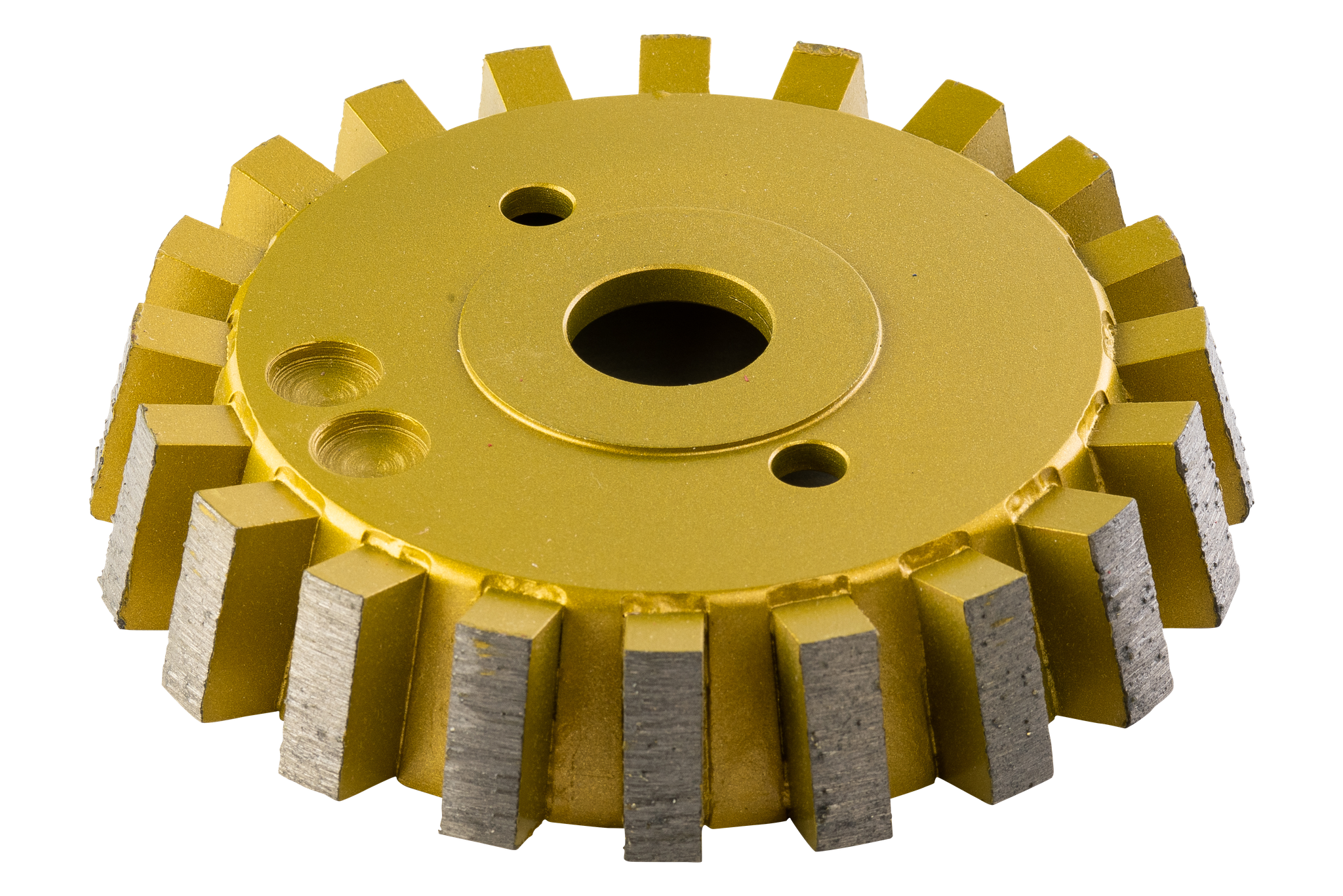

Depending on the surface, ASTILLO has developed adapted tools (milling cutters):

- For concrete removal --> Diamond segment tools

- For the removal of coatings such as resins, glues, plasters --> PCD segments tools (Polycrystal Diamond)

- For metal surfaces but also for hard concrete surfaces --> Diamond tools

And can also design a specific tool according to a particular need.

What equipment is used?

Different machines have been developed to meet different worksites configurations.

-

Manual mode

-

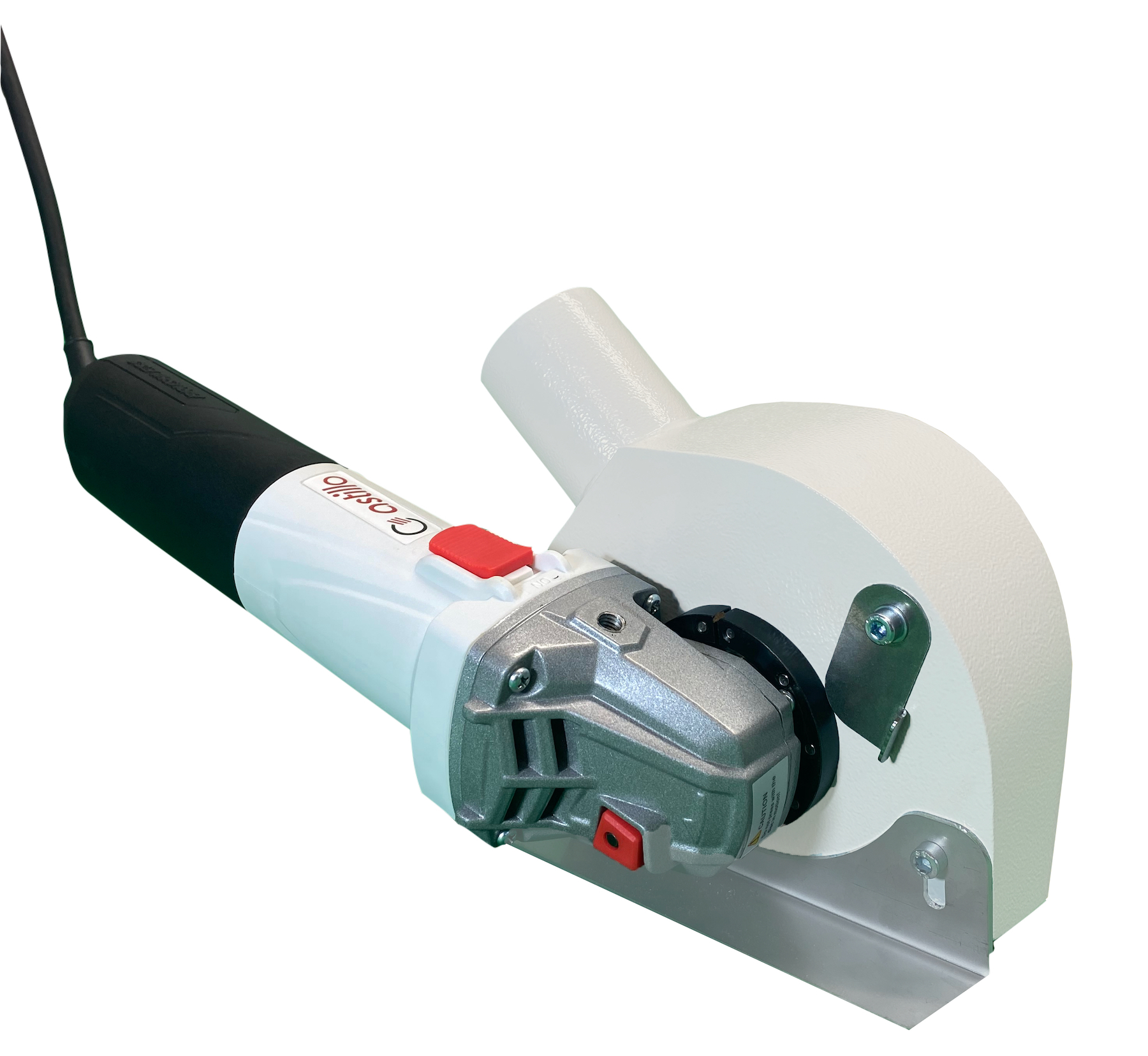

- Manual milling machine A80

-

-

- Possibility to use a system to support the tool "Ergo System"

-

- Manual angle milling machine C25

Working width : 25 mm

- Manual support for wall

-

- Ergo System

It is equipped with a guide carriage with 6-position height adjustment and an adapter to hold an A80 hand machine. By turning the carriage, 12 strips can finally be produced without having to change the height of the guide rail! The Ergo system allows you to work in regular horizontal strips without having to carry the machine!

- Semi-automatic mode for wall

-

- Wall Milling Machine AWF160

The milling head moves in two axes on a vertical mast placed on a mobile frame. It is controlled from a steering console.The milling head allows a working width of 160 mm with an adjustable depth of up to 12 mm.The milling tools are compatible with the A160 duo floor or ACF 160 ceiling milling machine.This system allows 4 strips of 160 mm (5-6 mm overlap between strips) to be made before the operator has to move the carrier.Changing from one strip to another is simplified by the indexing system on the horizontal rail, which allows the tool to be quickly positioned into the right place.

-

Manual support for ceilings

-

- Ceilling milling machine ACF160

The patented rail system is fixed on a support (mobile scaffold, rolling platform, lifting platform). The lateral guide rails have pre-set indexing to enable joint belt operation.

- Floor milling machine A160 Duo

The floor milling machine has been designed to allow the removal of the hardest or most problematic coatings (bituminous glue,

etc.).

Manual milling machine A80

Floor milling machine A160 Duo

Ceilling milling machine ACF160

Wall Milling Machine AWF160

Full system: capture at source and waste conditioning

- Power: 12,5 kW

- Depression: 285 mbar

- Air flow rate: 1099 m3/h

- Filter: HEPA H13/H14

- Filter surface: 1000 dm2

- Pneumatically cleanable

- Max. flow rate: 1100 m3/h

This in-line vacuum controller detects insufficient vacuum and automatically stops the machine (hand milling machine, semi-automatic...).

- It emits a visual and audible signal.

- The switching point can be set between 5 and 25 mbar.

What are the pros?

REDUCED HARDSHIP :

Ergo System for wall: Allows ergonomic support and the move of the manual machine during operations using a rail system.

Semi-automatic wall milling machine AWF160

The small size and weight of the machine allows quickly access to any surface to be treated. The areas not accessibles are limited. The work is done with a minimum of hardship.

Ceiling milling machine ACF160 :

The rail system contacts the ceiling via an ingenious manual lifting mechanism and then

is moved

horizontally.The ergonomically optimised handling allows for long working cycles.

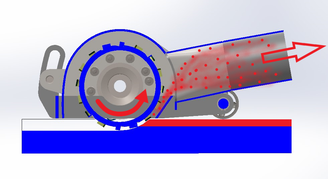

EFFECTIVE DUST COLLECTION:

For grinders, the disc rotates parallel to the surface: the centrifugal force ejects laterally the dust on 360° and can therefore, despite the presence of covers and flaps, eject the dust outside.

For milling machine, the milling cuts directly into the thickness of the material by rotating perpendicular to the surface. This makes it easier to collect dust as it is automatically guided to the suction nozzle.

Low dust emission certification for asbestos removal work in Germany < 2 fibers/l when processing floors, walls, ceilings and corners using the

full waste conditioning system.

ADAPTABLE:

The working depth of the various machine is continuously adjustable from 0 up to 12 mm by an adjusting screw.

The 160 mm milling tools are suitable for floor, semi-automatic wall and ceiling milling machines!

REPRODUCTIBLE:

Respecting the thickness milled: adjusting the thickness to be removed on the milling machine and keeping the milling machine in contact with the wall -> the removal cannot be greater than the defined value.

THE FINAL END STRATE OF THE SURFACE ALLOWS A SURFACIC RADIOLOGICAL CONTROL:

Technical Data Sheet

For more information, attend a demonstration...