Ultrasounds

How it works?

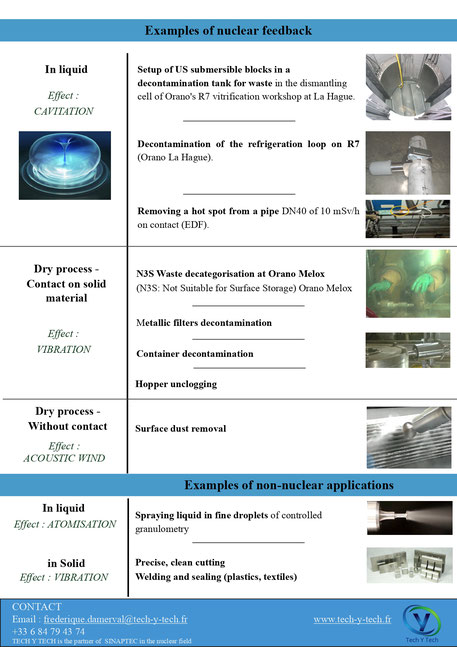

Depending on the environment (liquid, solid, gas), the phenomena created by ultrasounds are different, making it possible to meet the needs of a wide range of applications. The table below summarises, depending on the environment, the effect induced and some interesting nuclear applications.

Liquid

Effect: Cavitation

- Surface decontamination (≈ 20 KHz)

- Sonochemistry (≈ MHz)

Effect : Atomisation

- Spraying fine droplets

Solid

Effect: Vibration

Ultrasound produces a vibratory excitation on the material with an amplitude of a few microns, resulting in a vibratory force of a few millimetres > to the Van der Waals force. The particles will be detached from the surface, allowing applications such as:

- Unclogging filters and sieves

- Removal of fine, slightly encrusted particles from metal surfaces

Ultrasonic vibration also reduces the coefficient of friction between particles, which also makes it possible to use ultrasound for:

- Cutting materials (e.g. bitumen)

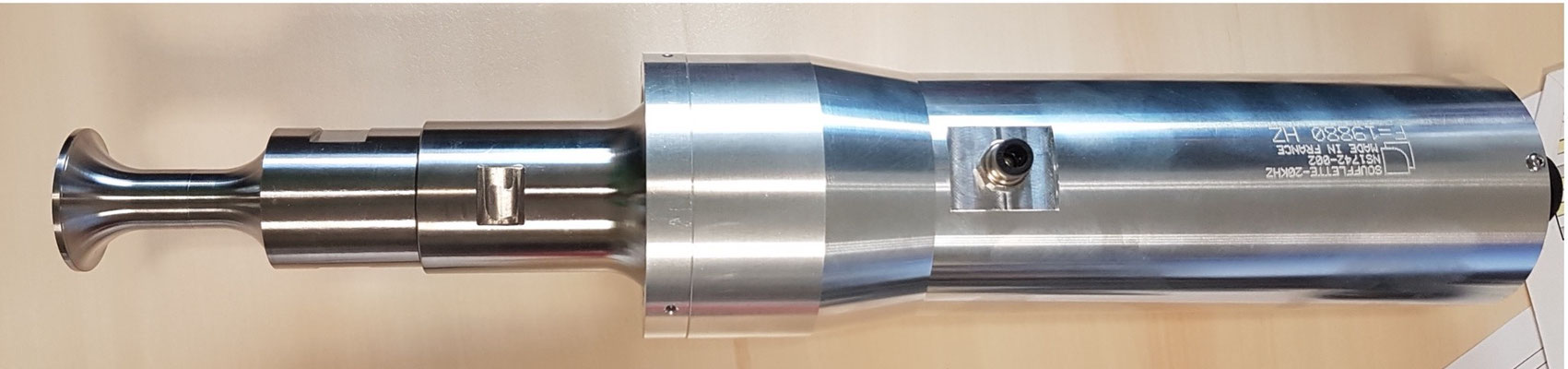

Gas

Effect: Acoustic wind

Ultrasonic technology produces an acoustic wind in front of the probe without any gas displacement. : The focusing of the acoustic waves produced by the US probe creates a pressure field a few centimetres away which causes the particles to move..

This acoustic wind phenomenon can be used for:

- Surface dusting (e.g. ultrasound blower)

- Defoaming

Examples of applications?

In Liquid:

Effect : Cavitation

-

Surface decontamination

-

Removing hot spots in pipes

Cavitation bubbles, which are created when they encounter a solid surface, implode on this surface, forming very violent microjets of liquid (100 m/s) that allow surface decontamination.

To obtain a good decontamination factor, it is important to choose:

- The power in W/l

- Ultrasonic frequency

Examples of feedback from equipment designed by SINAPTEC:

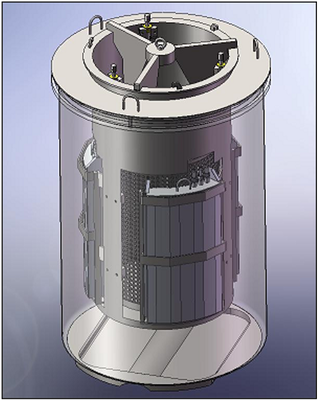

- Setup of US submersible blocks in a decontamination tank for waste in the dismantling cell of Orano's R7 vitrification workshop at La Hague.

- Decontamination of the refrigeration loop on R7 (Orano La Hague).

- Removal of a hot spot on DN40 flat piping with 10 mSv/h on contact (EDF).

In solid:

Effect: Vibration

-

Removal of fine particle deposits from equipment (tanks, valves)

-

Dry decontamination

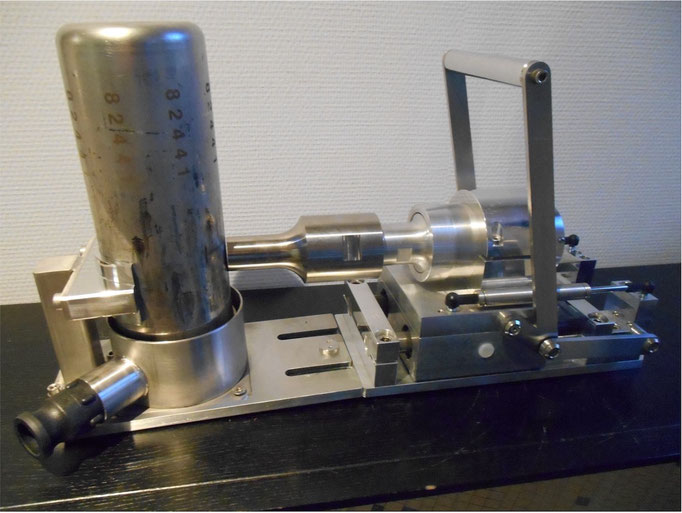

- Filter cleaning (sonotrode on metal filter)

Ultrasound produces a vibratory excitation on the material with an amplitude of a few microns, resulting in a vibratory force of a few millimetres > to the Van der Waals force. The particles will be detached from the surface.

Examples of feedback from equipment designed by SINAPTEC:

- Waste decategorisation at Orano Melox

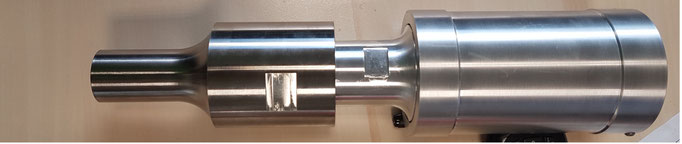

Example of the clean-up of PuO2-contaminated stainless steel cans at Orano MELOX

- Cleaning a valve

- Metal filter cleaning

In Gas:

Effect: Acoustic Wind

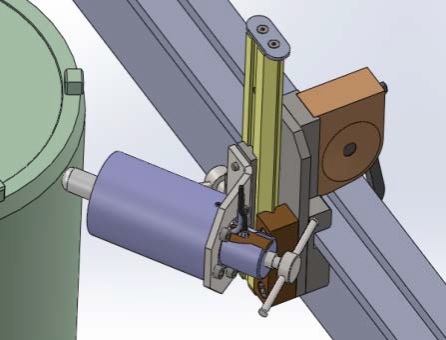

- Surface dust removal

Ultrasonic technology produces an acoustic wind in front of the probe without any gas displacement.

Examples of feedback from equipment designed by SINAPTEC:

Watch the presentation of Sinaptec in the nuclear sector

Technical data

If you would like to discuss your needs and study the possibility of using ultrasound for your application ... ?